OEM (Original Equipment Manufacturer) parts are crucial for modern vehicle crash repair services due to their specific design and engineering, ensuring optimal fit, safety, reliability, and structural integrity. Balancing quality, cost, and turnaround time is essential; OEM parts offer precise fitting, superior quality, enhanced resale value, and reliable repairs, while aftermarket parts are cheaper but may require more installation time. Integrating OEM parts into repair workflows requires researching reputable suppliers, ensuring compatibility and performance, training technicians, and prioritizing customer satisfaction to foster trust.

In the realm of vehicle crash repair services, selecting the right parts is paramount to ensuring safety, quality, and customer satisfaction. Original Equipment Manufacturer (OEM) parts stand out as a game-changer in this industry, offering both functionality and benefits. This article explores the significance of OEM parts, delving into their role, advantages, and potential drawbacks compared to aftermarket alternatives. We also provide best practices for integrating OEM components seamlessly into your vehicle crash repair workflow.

- Understanding OEM Parts: Their Role and Benefits in Crash Repair

- The Pros and Cons of Using OEM vs Aftermarket Parts

- Best Practices for Integrating OEM Parts into Your Vehicle Crash Repair Workflow

Understanding OEM Parts: Their Role and Benefits in Crash Repair

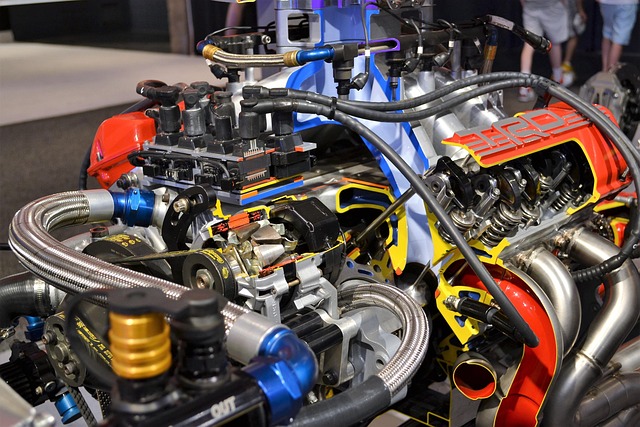

OEM (Original Equipment Manufacturer) parts play a pivotal role in modern vehicle crash repair services. These genuine components are designed and engineered specifically for a particular make and model, ensuring optimal fit and performance. Unlike aftermarket or replacement parts, OEM pieces are built to meet the exacting standards set by the vehicle manufacturer, guaranteeing both safety and reliability during the repair process. This is particularly crucial in collision repair services, where accurate fitting and high-quality materials can significantly impact the overall structural integrity of the car body repair.

By utilizing OEM parts, auto frame repair specialists can achieve precise restoration of the vehicle’s pre-accident condition. These parts are not just substitutes; they are designed to fit seamlessly into the existing structure, ensuring that the car body repair is both functional and aesthetically pleasing. This level of precision is essential for maintaining the safety features and systems that modern vehicles rely on, such as crumple zones and advanced airbag mechanisms. Ultimately, choosing OEM parts in vehicle crash repair contributes to a more secure and effective collision repair process, enhancing the overall quality of auto frame repair services.

The Pros and Cons of Using OEM vs Aftermarket Parts

When it comes to vehicle crash repair, choosing between Original Equipment Manufacturer (OEM) and aftermarket parts offers a balancing act. OEM parts, sourced directly from the vehicle manufacturer, boast several advantages. They ensure precise fitting, superior quality, and a seamless integration with your car’s existing systems, ultimately leading to a more reliable repair. Moreover, using OEM components can enhance the resale value of your vehicle, as these parts are known for their durability and ability to maintain the original aesthetics during auto detailing and vehicle restoration processes.

However, aftermarket parts present an array of alternatives at often lower costs, making them appealing for budget-conscious car repair services. These parts can be readily available, allowing for quicker turnaround times in crash repairs. While they may not always match the exact specifications of OEM parts, advancements in manufacturing have significantly improved their quality and compatibility. Nevertheless, using aftermarket components might require more time for installation due to potential differences in design and fitment, which could impact the overall efficiency of vehicle restoration processes.

Best Practices for Integrating OEM Parts into Your Vehicle Crash Repair Workflow

When integrating OEM (Original Equipment Manufacturer) parts into your vehicle crash repair workflow, it’s crucial to establish best practices that ensure quality and customer satisfaction. Begin by thoroughly researching and partnering with reputable OEM part suppliers who can provide authentic and up-to-date components. This step is vital as using genuine parts guarantees compatibility, performance, and safety during the repair process.

Additionally, train your auto body shop’s technicians to identify and work with OEM parts effectively. Educate them on the unique specifications and installation requirements of these parts. This knowledge will enable them to perform precise repairs, ensuring that car paint services align perfectly with the vehicle’s original design. In the world of vehicle repair services, prioritizing the use of OEM parts is a game-changer, fostering trust among clients who demand top-notch auto body shop craftsmanship.

When it comes to vehicle crash repair, integrating Original Equipment Manufacturer (OEM) parts offers a compelling blend of quality and efficiency. By understanding the unique benefits of OEM parts and implementing best practices for their use, repair services can enhance customer satisfaction and streamline their workflow. While there are considerations regarding cost and availability, the advantages of OEM parts in ensuring superior repair outcomes and maintaining vehicle integrity are undeniable. Embracing these strategies allows repair professionals to deliver top-tier service, fostering trust and loyalty among their clientele.